In the rapidly evolving landscape of modern dentistry, digital technologies have revolutionized implant planning and restoration processes. Among these innovations, multi-unit scan bodies play a pivotal role, enhancing accuracy, efficiency, and patient outcomes in implant dentistry. This article explores the significance of multi unit scan body, their benefits, clinical applications, and future directions.

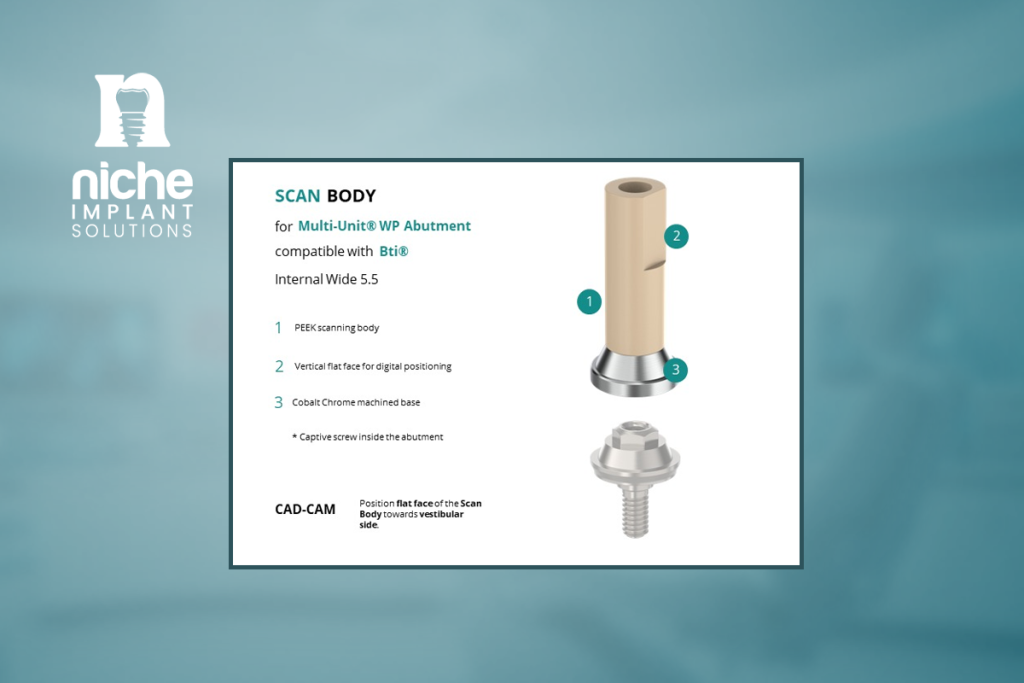

Multi unit scan body are precision-engineered components used to transfer the exact position and orientation of dental implants into digital format. They replace traditional impression techniques by facilitating direct scanning of implant positions, allowing for seamless integration with CAD/CAM systems.

Enhancing Precision and Efficiency: Unveiling the Benefits of Multi unit scan body in Implant Dentistry

Multi unit scan body offer several benefits in the field of implant dentistry, which contribute to enhanced precision, efficiency, and overall treatment outcomes. Here are the key benefits:

Precision and Accuracy

Multi unit scan body enable precise replication of implant positions and orientations in digital format. This accuracy minimizes discrepancies that can occur with traditional impression techniques, ensuring that prosthetic components fit perfectly onto implants.

Efficiency in Workflow

By eliminating the need for physical impressions, multi-unit scan bodies streamline the treatment workflow. Dental professionals can directly scan implant positions and integrate the digital data seamlessly into CAD/CAM systems. This reduces chairside time and facilitates quicker design and fabrication of prosthetic restorations.

Predictable Treatment Outcomes

The digital precision provided by a multi unit scan body leads to predictable treatment outcomes. Dental teams can plan and execute implant placements with confidence, knowing that the final restorations will align accurately with the patient’s anatomy and functional requirements.

Versatility in Clinical Applications

Multi-unit scan bodies are versatile and applicable in various clinical scenarios, including full-arch restorations, complex implant cases, and implant-supported overdentures. They facilitate accurate capture of multiple implant positions and support the design of comprehensive prosthetic solutions.

Enhanced Patient Comfort

Digital workflows enabled by multi unit scan body contribute to improved patient comfort. Patients experience fewer visits and reduced chair time during the implant treatment process. The accurate fit of prosthetic restorations also enhances comfort and functionality post-treatment.

Facilitation of Digital Integration

The digital data obtained from a multi unit scan body seamlessly integrates with CAD/CAM software. This integration allows for precise design and customization of abutments and prosthetic restorations, ensuring optimal aesthetic and functional outcomes for patients.

Cost Efficiency and Long-Term Savings

While initial setup costs may be involved, adopting multi-unit scan bodies can lead to long-term cost savings. Reduced chairside time, fewer material costs associated with traditional impressions, and fewer adjustments needed for prosthetic fittings contribute to overall economic benefits.

Multi unit scan body represent a significant advancement in implant dentistry, offering dental professionals the tools to achieve superior clinical outcomes with efficiency and precision. Embracing these technologies enhances the quality of care delivered to patients, providing predictable and durable solutions for implant-supported restorations.

Digital Precision vs. Traditional Techniques: A Comparative Analysis in Implant Dentistry

When comparing multi unit scan body to traditional impression techniques in implant dentistry, several factors highlight their advantages in terms of efficiency, accuracy, cost savings, and time management:

Efficiency and Accuracy

Multi-Unit Scan Bodies

- Precision: Multi-unit scan bodies utilize digital technology to capture precise data of implant positions and orientations directly. This digital process minimizes human error and ensures consistent accuracy in replicating the patient’s oral anatomy.

- Workflow Integration: Digital scans from multi-unit scan bodies seamlessly integrate with CAD/CAM systems. This integration allows dental professionals to design and fabricate prosthetic components with meticulous detail, optimizing fit and function.

- Time Efficiency: The digital workflow with multi-unit scan bodies reduces chairside time significantly. There is no need for traditional impression materials, tray preparation, or patient discomfort associated with traditional methods.

Traditional Impression Techniques:

- Potential for Errors: Traditional impressions involve physical materials that may distort or inaccurately capture the implant positions and soft tissue contours. Errors in impression-taking can lead to misfitting prosthetics and require additional adjustments.

- Laborious Process: Traditional methods require several steps, including impression material mixing, tray placement, and patient waiting times for material setting. This process can prolong treatment sessions and may necessitate multiple appointments for adjustments.

- Dependency on Clinician Skill: Successful traditional impressions heavily rely on the clinician’s skill and experience in achieving accurate results. Variability in technique among practitioners can impact consistency in prosthetic fit.

Cost and Time Savings with Digital Workflows:

Multi-Unit Scan Bodies:

- Reduced Material Costs: Digital workflows eliminate the need for impression materials, trays, and disinfection solutions associated with traditional methods. This reduction in consumables lowers operational costs over time.

- Minimized Chairside Time: The efficiency of digital scans with multi-unit scan bodies translates to fewer chairside appointments and reduced overall treatment duration. Patients benefit from shorter visits and quicker turnaround times for prosthetic delivery.

- Fewer Adjustments: The precise fit achieved through digital workflows decreases the likelihood of prosthetic adjustments post-placement. This saves both clinician and patient time and reduces the need for additional chairside adjustments.

Traditional Impression Techniques:

- Material and Labor Costs: Traditional methods involve ongoing costs for impression materials, trays, and disinfection supplies. Additionally, the labor-intensive nature of impression-taking can result in higher overall operational expenses.

- Extended Treatment Time: Multiple appointments for impression-taking, material setting, and adjustments can extend the total treatment duration. This may inconvenience patients and impact practice scheduling.

- Potential for Remakes: Inaccurate impressions may necessitate remakes, leading to additional material costs and patient visits. Clinicians may also need to allocate more time for adjustments to achieve an acceptable prosthetic fit.

A multi unit scan body offers significant advantages over traditional impression techniques in implant dentistry. They enhance efficiency and accuracy through digital workflows, leading to predictable treatment outcomes and improved patient experiences. The adoption of digital technologies not only reduces costs associated with materials and chairside time but also enhances practice productivity and patient satisfaction. Embracing these advancements allows dental professionals to deliver superior implant treatments with precision and confidence, setting new standards for quality care in modern dentistry.

Integration of Multi-Unit Scan Bodies with CAD/CAM Systems

In the realm of modern implant dentistry, the integration of multi unit scan body with CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) systems represents a pivotal advancement. This seamless interaction enhances precision, efficiency, and overall treatment outcomes in implant planning and restoration.

Also look: Unveiling the new type of dental implants : 3D-Printed Dental Implants

How Multi unit scan body Interface with CAD/CAM Software

Multi unit scan body are designed to facilitate the accurate transfer of implant positions and orientations into digital format. Here’s how they interface with CAD/CAM systems:

- Digital Scanning: Dental professionals use intraoral scanners or desktop scanners to capture detailed images of the implant positions with attached multi-unit scan bodies. These digital scans generate precise 3D models of the patient’s oral anatomy.

- Data Acquisition: The digital data captured by multi-unit scan bodies is transferred directly to CAD software. This includes information on implant location, angulation, and depth, critical for designing customized prosthetic components.

- Design and Planning: CAD software processes the scanned data to create virtual models of the final prosthetic restoration. Clinicians can manipulate these models to optimize the fit, aesthetics, and function of the restoration before fabrication.

- Fabrication: Once the design is finalized, CAM software translates the digital design data into manufacturing instructions for milling machines or 3D printers. This automated process ensures the precise fabrication of prosthetic components, such as abutments and crowns.

- Quality Control: CAD/CAM systems allow for meticulous quality control throughout the production process. Clinicians can verify the accuracy of the digital design and ensure that the final restoration meets the patient’s specific anatomical and functional requirements.

Advantages of Digital Implant Planning Using Multi unit scan body :

- Enhanced Precision: Digital implant planning with Multi unit scan body ensures unparalleled precision in capturing and replicating implant positions. This accuracy minimizes errors that can occur with traditional impression techniques, leading to superior prosthetic fit and occlusal harmony.

- Efficiency: The streamlined workflow facilitated by CAD/CAM integration reduces chairside time and eliminates the need for physical impressions. Dental teams can expedite treatment planning and delivery, improving practice productivity and patient satisfaction.

- Predictable Outcomes: Digital workflows provide clinicians with predictive capabilities, allowing them to visualize and simulate the final restoration before fabrication. This predictive insight enhances treatment predictability and patient communication, ensuring optimal outcomes.

The integration of the Multi unit scan body with CAD/CAM systems represents a transformative shift in implant dentistry. By harnessing digital technologies, dental professionals can achieve superior clinical outcomes with enhanced precision, efficiency, and patient-centered care. Embracing these advancements not only elevates practice capabilities but also sets new standards for quality and innovation in modern dental implant treatments.

Empowering Precision Dentistry: The Role of Niche Companies in Advancing Multi-Unit Scan Body Technology

Incorporating Multi unit scan body into the workflow of a niche dental solutions company not only enhances clinical capabilities but also sets new standards for quality and innovation. By embracing these advanced technologies, dental professionals can deliver exceptional care that prioritizes precision, efficiency, and patient satisfaction. As the field of implant dentistry continues to evolve, multi-unit scan bodies remain at the forefront, empowering dental teams to achieve predictable and durable results that elevate the standard of oral healthcare.

Contact Niche Dental Now : Experience the Difference

Call us on +201011687002

Location : Cairo٫Zahraa Elmaady٫ Carrefour St٫ 10058

0 Comments